|

|

People Behind The Scenes

My 41 year career working at

the Chrysler Engineering Centers

by Ed Poplawski

|

|

|

|

I started at Chrysler engineering on March

23, 1966 and was hired to work in the Engine Performance

and Endurance Testing area. My first 2 weeks were in the

Endurance Testing area where there were 5 test cells each

with 2 engines in each cell running 24 hours a day. My

job was to take hourly readings on all the engines running

and to perform periodic maintenance on them like oil changes,

etc. We also did tests on the engines to evaluate their

performance like Nitro checks (where you pumped large

amounts of nitrogen into each cylinder through the spark

plug hole and look for air bubbles in the coolant system

to check for leaking head gaskets), Compression checks,

putting purple dye in the coolant and checking the outside

of the engine with a black light to look for water leaks.

Every so many hours you would shut the engine down and

pull the oil pan to do a bearing inspection, pull the

heads to check the valves and valve seat wear, and do

a carbon cleaning of the combustion chambers and piston

tops. The reason for this was because back then we used

leaded gas and there would be build-up on these parts

and we would clean these parts so the engine would run

at peak performance. We also replaced gaskets or bearings

or piston rings or pistons or valve train components like

springs and rocker arms, or any other parts of the engine

at periodic intervals to determine wear and endurance

of these parts. This went on 24 hours a day, 7 days a

week, 365 days a year. Next, I was assigned to a Performance

Engine dyno test cell where there is one operator in a

cell with one engine and one dyno. I worked in various

Performance / Race test cells for the next 24 years and

worked on many and varied engine programs. For example,

Australian Six (which is the very first engine I broke

doing WOT power testing), 440-6bbl, 340-6 bbl, Thermoquad

development for the 340, NASCAR and NHRA race engine development

like the 355” race engines, Pro-gas 288” drag

engines, Road Runner 383”, Street Hemi development

and Ball-Stud Hemi development (400” & 444”),W-2

cylinder head development, Variable venturi carburetors,

Super Six, 2.2L & 2.5L Turbo 1 &II, 4-valve Lotus

and Maserati head development, and Single cylinder engine

development. I also spent 3 years in the Air Flow lab

developing and evaluating various cylinder head and port

designs for our engines like the “fast burn“

combustion chamber.

|

|

CLICK ON IMAGES TO ENLARGE

|

|

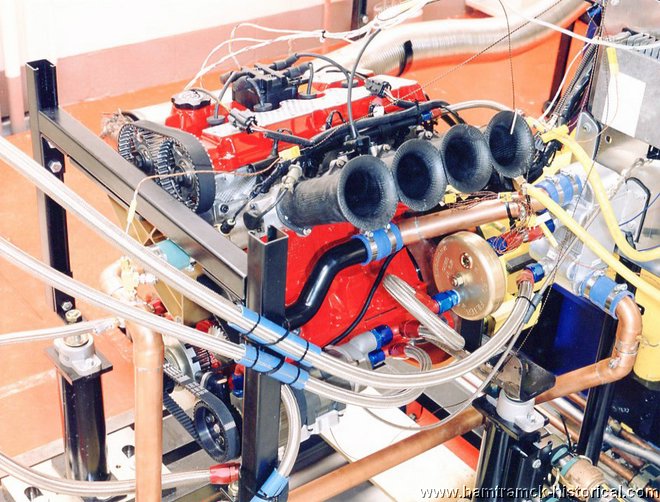

The black & white one photo is taken in Room 13 before

I ran a WOT power check. The 3 colored ones are of me in

Room 7A. The engine is an 8-bbl – 288 cubic inch Pro-Gas

drag motor. We ran WOT power runs with this engine from

6400 – 10,000 rpm, taking readings every 400 rpm. Those

were great days.

|

Room 7A

Room 7A

Room 7A

Room 13

Chrysler I.D. badge

Chrysler I.D. badge

Lab coat patch

The LCP Engineering sign was on

the window entering our suite at CTC on the 3rd floor.

We were attached to “Large Car Platform” since we were

racing the Intrepid which was a Large Car Platform vehicle.

Chrysler enamel stick pins - The

"JA" pin was for the Cirrus – Stratus program which was

the program I.D. The “LH Team” was for the original Intrepid

and Chrysler back in the early 1990’s, the “Chrysler 300M”

was obviously for that program, the “7 Year – 70,000”

mile pin is obvious, the Ram Truck pin was for the Truck

Racing program when we got back into NASCAR in 1995, and

then there is the new Chrysler logo pin.

Here is the memento we got when

we moved into the new Chrysler Technical Center in 1991.

A piece of the granite is enclosed in a plastic container

hooked to a key chain.

DaimlerChrysler badge

|

Performance testing was different than Endurance testing

in that you were trying to optimize the actual performance

of the engine as far as torque and horsepower and fuel

economy and spark advance. You were trying to get the

most bang for the buck. We would try all sorts of new

parts like modified intake and exhaust manifolds, changing

the camshaft or camshaft timing or the camshaft events,

various spark plugs, different cylinder head port and

combustion chamber designs, additional carburetors and

different type and sizes of exhaust systems, change the

jetting of the carburetors, use different spark advances

and air cleaners and air filters, different ratios of

water pump pulleys, windage trays, etc.

The engines were instrumented with thermocouples in each

port of the exhaust manifold to measure exhaust gas temperatures,

stainless steel sampling tubes were also installed in

each exhaust port to sample the exhaust gas itself to

determine the fuel / air ratio of the engine and the emissions

of the engine, a 6” deeper oil pan was installed

so that the performance would not be affected by the windage

in the crankcase, thermocouples were also installed in

the air cleaner inlet and in other places of the engine

depending on the type of data we were looking for. Testing

involved either part throttle or wide open throttle tests

starting at 800 rpm and going up to 6000 rpm depending

on the type of engine we were running, taking all of our

readings at 400 rpm intervals. We would read torque, horsepower,

spark advance, oil and water temperature, air temperature,

fuel flow, exhaust gas temperatures, fuel / air ratios,

air flow, vacuum in the intake manifold, etc. At the end

of the test we would bring the engine back down to 800

rpm, shut off the fuel and the spark, and go back up through

the speed range with the throttle wide open and measure

the friction at each speed. After the test the test engineer

would calculate and plot the data and talk with his manager

and they would plan the next changes to be done to the

engine. Then I would perform those changes and we would

repeat the process over and over again until we got the

performance we were looking for.

Up until the mid 1970’s when OSHA was created by

Congress to monitor health and safety issues, the dyno

operator and test engineer were in the test cell with

the engine 6 feet away running at speeds up to 6000 rpm

with no protection whatsoever except for ear muffs. The

exhaust systems would be red hot, the noise was unbelievable,

and when parts and pieces of the engine broke it was all

men for themselves as we dodged them and got out of the

cell. And this was an everyday occurrence. After OSHA

came into existence 6’’ thick walls with bullet

proof glass and sound deadener were installed between

the operator and the dyno/engine for their safety and

protection. What an improvement that was! However, the

test cells which were used for full race engine development

always had a steel wall and bulletproof glass between

the engines and the operators because the speeds we tested

at were much higher (up to 10,000 rpm) and when an engine

broke usually the damage was extensive to the engine and

in some cases fires would break out. All the test cells

had CO2 fire extinguishers in the ceilings to put out

any fires that would occur. Many times when a crankshaft

broke it would fall downward and literally rip the oil

pan off the engine and all the oil would splash everywhere

and usually cause a fire. Connecting rods breaking were

also interesting because many times the rod would jam

itself between the bottom of the piston and the crank

and the engine would come to an immediate and abrupt stop.

Now that was entertaining!!!

|

Part 2

On a hot sweaty day in July, 1990 I was under a 3.2L engine

checking the bearings when an old friend and ex race dyno

guy and drag racer, Ted Flack, came into my test cell

and asked if I wanted to go upstairs and work for him

at a nice, clean, cool desk. Ted was the Manager of the

Prototype Engine Build and Procurement area. I couldn’t

say “YES” fast enough and I started my second

career at Chrysler the following Monday. He wanted me

to handle the procurement of all prototype engine parts

for our future engines. This job would continue until

May 31, 2007 (17 years) when I retired.

On Labor Day weekend 1992, we moved from the Engineering

Center in Highland Park, Michigan to the new Chrysler

Technical Center (CTC) in Auburn Hills, Michigan. What

a palace!!

The first program I worked on was the new 3.5L engine

for the LH car. This was to be followed by the 3.2L, and

the 2.7L engine. When I speak of prototype engines I am

referring to the very first engines built of a new engine

program. All the parts were procured from specialized

shops and not from production suppliers as the quantities

were very low. For example the first phase and the second

phase might only be 25 or 50 engines which was followed

by the final phase of around 200 engines. These engines

were used strictly for dyno testing and in-car testing

to verify the design, performance, and endurance of the

particular engine. This part of the program lasted around

1 year until all the bugs are worked out and this gives

the production plants time to install the new equipment

to produce these engines. Then we also use some of the

very first production engines built on the line for final

validation before the engine goes into high volume production.

Around 1996 a new racing series was started in the United

States called “Touring Car Racing”. This series

is and was very popular in Europe and involved sedan racing

on road courses. Management decided to get involved in

this and we had 2 cars built in house (Dodge Stratus)

and we did the engine development in house also using

our 2.0L engine. I was responsible for procuring all the

parts needed to do this. This series lasted only about

2 years and really never caught on here. Dodge won the

1997 Championship with David Donohue driving.

The following year (1995) Dodge got involved in the new

NASCAR Craftsman Truck Racing series and this was the

beginning of our return to full time NASCAR racing in

2001. In the summer of 1999 the Race Engine Group was

resurrected with Ted as the Manager , I did Procurement

of all parts, Dave Eovaldi was brought on for camshaft

and valve train development, Neil Loughlin for cylinder

block and structure development, Pat Baer did intake manifold

and cylinder head design and development, Dave James was

our Chief designer, and Rudy Sayn did what ever else there

was to do to get an engine designed. We had a design finalized

by December 1999 and we had our first engine running in

May 2000 down at Everham’s race shop. This engine

was the R5/P7. R5 designating the block design and P7

the head design. Eventually, besides handling all the

engine parts I was responsible for many of the body parts

and panels, fasteners, contracts for additional support

for the teams, and other miscellaneous parts needed to

go full time racing. Right before I retired we were working

on the next version of our 355” NASCAR race engine

which was designated the R6/P8. We had a warehouse down

in Charlotte, North Carolina to store all these parts.

Had the chance to go to some of the races, meet the drivers,

and in general had a great time (and they paid you for

this too!!).

|

|

CLICK ON IMAGES TO ENLARGE

|

Work Area 1/5

Work Area 2/5

Work Area 3/5

Work Area 4/5

Work Area 5/5

Left to right: Ed Poplawski, Kent

Wallace, Neil Loughlin, Pat Baer, Dave James, Rudy Sayn,

Dave Eovaldi

Left to right clockwise: Ed Poplawski,

Pat Baer, Neil Loughlin, Roger Doll, Ted Flack, Dave James,

Dave Eovaldi, Alona Pehrson, Rudy Sayn, and Barbara McNeil

in the middle

Ed's 35th Anniversary

Countdown to Daytona

Ed Petty :-)

Business Card

Kimble

R5P7 cutaway

Arrington race shop: Left to Right:

Ray Richards, Joey Arrington, Ted Flack, Kyle Petty, Alona

Pehrson, Richard Petty, Ed Poplawski, Roger Doll

Petty engine shop: Left to Right:

Ed Poplawski, Maurice Petty, Alona Pehrson, Richie Petty

Petty Racing Experience

Richard Petty Museum

Chicagoland Race Track

|

|

|

|

CLICK ON IMAGES TO ENLARGE

|

CTC Museum Engine Dedication

Left to Right: Ray Evernham, Floyd Allen, Ted Flack, Rudy

Sayn, Dave Eovaldi, Pat Baer, Ed Poplawski

Outstanding Contribution to the

P7 Project and 2001 Dodge Manufacturer's Championship

Engine Builder of the Year - 1st

Place

40 Year Plaque

|

DaimlerChrysler Retirement Badge

Retirement Party

|

Updated information from

Ed on The John Wehrly Album

|

"This picture from The John Wehrly

Album shows Ken Heatlie at the controls of the dyno and

Bob Lechner, the test engineer looking on. This photo was

taken in Room 40, Building 136 of the Chrysler Engineering

Center in Highland Park, Michigan where they were running

a Max-Wedge engine. This is a staged photo as the engine

is clearly not running. Also if a test was being done both

would have ear protection on. Up until mid 1970's, except

for the full race rooms, the dyno operators and the engineers

would be in the room while running the test with no protection

for them. Running WOT tests up to 6000 rpm with the exhaust

manifolds red hot was a common everyday thing. A driveshaft

connected the engine to the dyno and the driveshaft was

surrounded by a 1/4" steel guard. If there was an engine

failure it was all men for themselves to get out of the

room. As we used to say "feet don't fail me now". You can

see the stainless steel exhaust sampling tubes coming out

of the exhaust manifolds and going to the Cambridge Analyzer

where the engineer is writing down the fuel/air ratios."

- Ed Poplawski

|

|

"1978 Chrysler Race Engine Group:

Left to Right back row: Bob Zeimis, Jim Broske, Ed Poplawski,

Pete Wright

Left to Right front row: Al Nichols, Ken Heatlie, John Wehrly,

Jim Robertson, Bob Patterson" - Ed Poplawski

|

|

|